Welcome to Futurity Manufacturing,

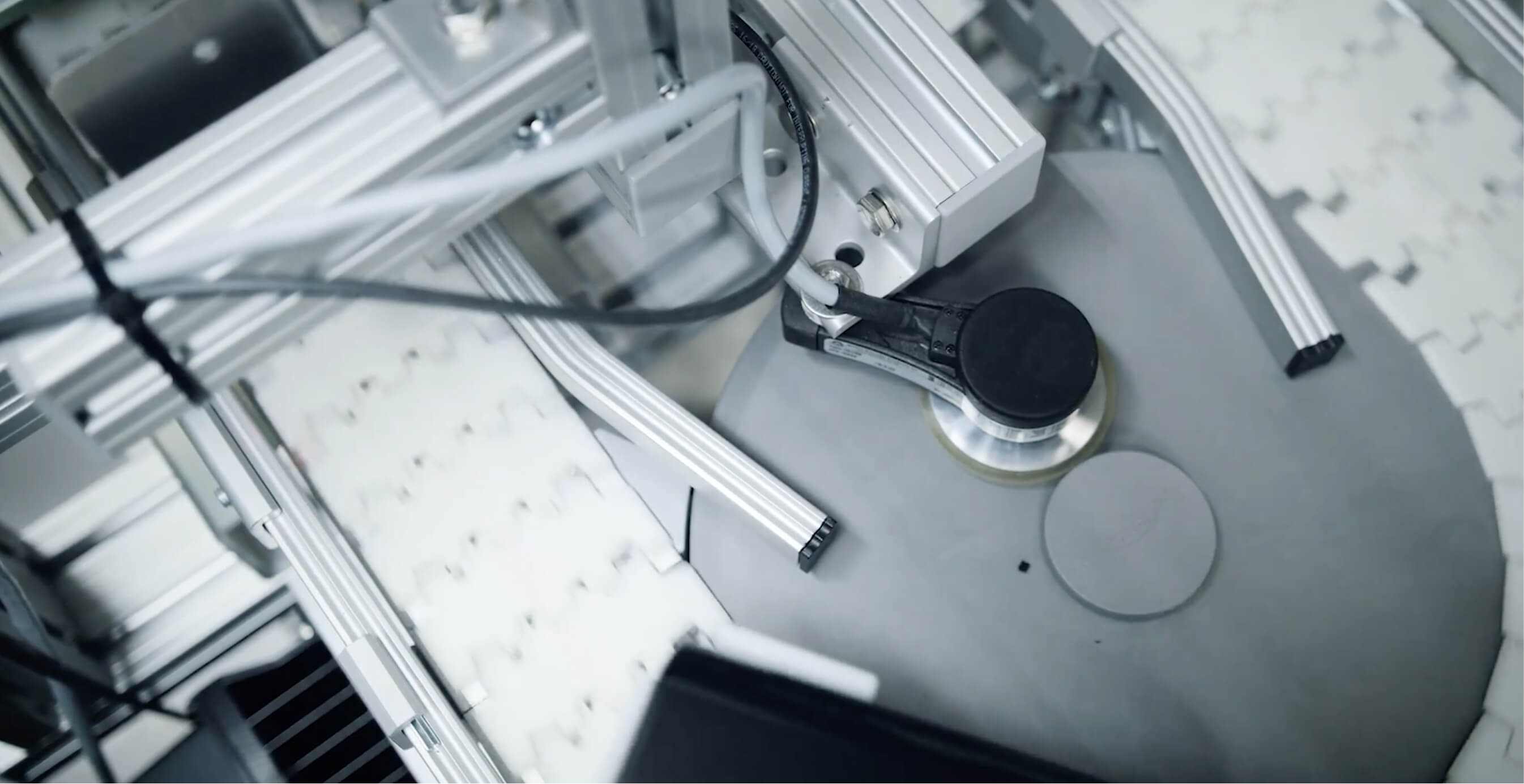

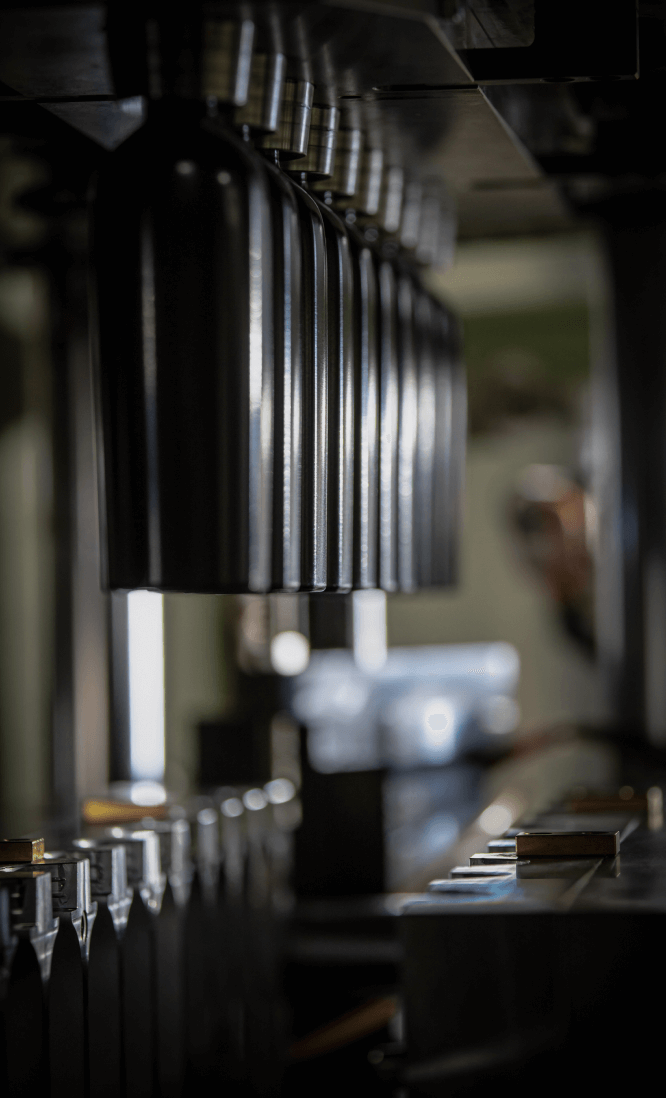

Introducing our new 650ml plant-based bottle filled with pure New Zealand water and designed to be disposed of in a commercial compost. Our bottles can be tailored to work within your brand needs and guidelines by customising the colour and design of every bottle with the use of our proprietary printing technology.

Order your free custom samples and find out more.

Products for the future.